Renping Liu

Head of UCOT Research Institute

B.E.(Hon) and M.E. degrees from Beijing University of Posts and Telecommunications, China, and the Ph.D. degree from the University of Newcastle, Australia. Professor at the University of Technology Sydney, Former Principal Scientist at CSIRO, the winner of Australian Engineering Innovation Award and CSIRO Chairman’s medal.

UDT TECHNIQUES ADVANYAGES

DEVELOPED BY SPECIALIZED BLOCKCHAIN AND IOT DEVELOPMENT

UDT has a strong autonomous R&D team. Chief Technology Officer, Professor Ren-ping Liu (professor of technology institute of electrical and data engineering at University of Technology Sydney, Former Principal Scientist at CSIRO) is leading an excellent technology team which includes elite scientists and computer network engineers. The team is dedicated to research and developing NB-IoT intelligent Internet design and network security based on blockchain.

UDT makes full use of its technical advantages and combines software with hardware to customize the solution of blockchain for various industries, providing reliable and extendable industrial ecosystem.

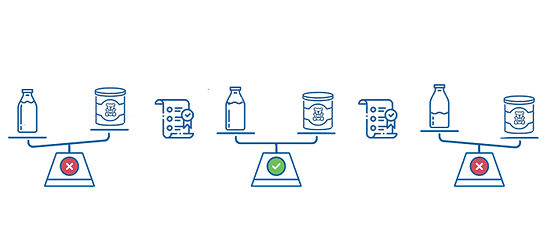

Origin Verification

UDT has a strong autonomous R&D team. Chief Technology Officer, Professor Ren-ping Liu (professor of technology institute of electrical and data engineering at University of Technology Sydney, Former Principal Scientist at CSIRO) is leading an excellent technology team which includes elite scientists and computer network engineers. The team is dedicated to research and developing NB-IoT intelligent Internet design and network security based on blockchain.

UDT makes full use of its technical advantages and combines software with hardware to customize the solution of blockchain for various industries, providing reliable and extendable industrial ecosystem.

Supply Chain Management Efficiency

Because the data recorded on the Blockchain is time stamped with solid proof and is tamper-resistant, the disputes between the parties involved in the supply chain system can easily be resolved by determining the responsibility based on proofs and tracking information. Trading parties participating in the supply chain can share the data with each other to achieve openness and transparency. The flow of information remains intact and unobstructed at all times, ensuring that that once there is any kind of problem, the supply chain system and the participating parties can detect where the problem is promptly and develop a solution quickly and objectively, thereby enhancing the overall efficiency of supply chain management. Therefore, Blockchain technology can avoid many unnecessary disputes along the supply chain.

An open and transparent supply chain can bring many benefits to the company and help build up its competitive advantage. For example, the Australian milk formula supplier began to include scan codes on the product tank so that consumers can retrace the product back to the manufacturer; this program alone can add more than $20m brand value to the company.

Certification

Product certification is an essential tool for enterprises' brand differentiation strategy, but it is often very difficult to verify the authenticity of the certification. While proving the integrity of the product certificating process is an expensive process, it is sometimes difficult to ensure the validity of the claim even after a painstaking auditing process. On a global scale, there are many areas with a lot of corruption, and noncompliant certificating schemes can in fact further endanger the credibility.

However, the supply chain data on UDT platform is collected by all parties at the same time, and the blockchain will efficiently allocate impartial incentives according to pre-programmed smart contract.

The UDT platform is an authentication system that can assign and validate certain attributes of a physical product, and implement a full-chain model of the various materials and components from the initial production through manufacture and assembly to the final customer. At each point in time, the prototype of the model will describe in detail five key properties concerning all materials and consumables it covers: the nature (what it is), the location (where it is), the quality (how it is), the quantity (how much it is) and the ownership (whose it is). The key attributs can be read and linked from pre-existing datasets such as barcodes, and reassigned along the supply chain.

Supplier Module

UDT provides a way to safely record the key information about the material during the transfer process.

After successful certification, these procedures are used by the supplier to prove materials or the creation of primary products. The program would specify and implement the parameters of each production equipment, including:

-

Certification of Production capacity, such as that the "raw milk/year” is 2,000 tons;

-

Production accounting, that is, production date, shelf life and sales registration;

-

Product classification, that is, a detailed description of the its origin and dairy cow breed, and any other "label" of the particular attribute;

These parameters can be adjusted according to the guidelines of the certifier or after the auditors' checks, and if the audit is unsuccessful, the procedure may be withdrawn as needed (temporarily). Since the program is primarily responsible for creating the product, the supplier module forms the source of the product traceability and then links to the digital identity provided by the registrar.

Manufacturer Module

The manufacturer module can realize the conversion of products from raw material input, to final product through the production process. Same as the suppliers' module, once deployed by the certification authority, the program would run automatically with the constraints by the manufacturer. Howerver, there is another constraint: the input must be "used" for any output, just like the physical world. For example, a certain supply amount of milk powder registration requires a corresponding amount of raw milk input. After the production process is completed, the amount of raw milk input would be erased. As the process on the Blockchain is auditable, only when the corresponding amount of raw milk consumption is no longer available, could the milk powder supply be generated.

Digital Chip Tracking Module

UDT uses self-developed electronic tags with NB-IoT standard chips, encrypted QR codes, and NFC labels to trace the physical products, the component andIn addition to the implementation of the above basic business logic, UDT also provides the user interface the origin that connects the product with its digital identity, so that customers on every downstream link along the supply chain can successfully carry out the purchase of goods from the upstream link.

Bar code and serial number will be hash encrypted and generate a digital link to the Blockchain via RFID and NFC or NB-IoT chip.

Registration Module

At the beginning, a UDT identity is created. In UDT, everyone can use his or her private key to access their information. Depending on use cases and permissions, the data can be set as public or private. Some may contain only anonymous IDs, while others may include complete information.

The program running on this module forms the basic trust relationship between the entire base of users and the system. The program will initially be deployed by the registrar, who will register for the designated participant (i.e., the certifier, the auditor, the supplier, and the manufacturer). Participants can register digital identities and then link the blockchain-based digital identity to the identity of the real world, and record the results in the Blockchain for inspection by all. When the platform is used, the Blockchain can automatically verify the digital identity. This module allows the participant to remain anonymous.

User Interface Module

UDT provides user-oriented applications to access security information about the product on the Blockchain. In the Blockchain-enabled supply chain, information of each transaction is auditable, and the smartphone application can read and display information to the custmer in real time by checking respective block. UDT's user interface can completely demonstrate the digitalized logistics process of the product, giving the end user a real option so that they can better implement the purchasing activities.